Logistics Scheduling Software in 2026 – A Complete Guide for Operations Leaders

If you manage logistics or operations, you know how important scheduling is. When trucks arrive late, the wrong people show up, or pallets sit around because no one’s on a forklift, everything slows down — and costs go up. Still, many logistics teams rely on spreadsheets, guesswork, and last-minute fixes. This guide explains why modern scheduling software isn’t just helpful — it’s essential. We’ll look at what makes a great logistics staff time tracking and scheduling tool, the pros and cons of using software, and how to put it in place. You’ll also see how tools like Shifts by Everhour can help solve everyday scheduling problems on the warehouse floor and in planning meetings.

🤔 What Is Logistics Scheduling?

At its core, logistics scheduling is the art and science of planning who and what goes where, and when. It includes everything from production and transportation planning to scheduling driver shifts and managing warehouse staff. A well-organized schedule makes sure that:

- 📦 Products are delivered on time

- ⚙️ Resources are used efficiently

- 🤝 Customer expectations are met

There are several key types of logistics scheduling that operations leaders should know about.

🛠️ Types of scheduling in logistics

- Production scheduling 🧪 – planning what to make, how much, and when. It helps avoid making too much or too little and keeps costs down.

- Transportation scheduling 🚚 – managing how goods move, choosing carriers, planning routes, and setting shipment times. Done right, it lowers shipping costs and keeps deliveries on time.

- Warehouse scheduling 🏢 – organizing activities like receiving, storing, picking, packing, and shipping. This improves space usage and cuts down on delays.

- Delivery scheduling 📬 – setting delivery times, planning last-mile routes, and updating customers. It helps make deliveries on time and keeps customers happy. Use delivery scheduling software to help with that!

- Maintenance scheduling 🔧 – planning regular checkups for vehicles and equipment to prevent breakdowns and keep things running smoothly.

- Demand forecasting and scheduling 📊 – predicting future demand and aligning production and transportation to meet it.

- Personnel scheduling 👷 – organizing shifts for warehouse workers, drivers, and office staff. This can be tricky, as labor costs are high and rules are strict.

When these areas work well together, the supply chain runs smoothly. But when they don’t, you risk missed deadlines, overtime costs, stressed employees, and unhappy customers.

That’s why modern logistics scheduling software has become a must-have tool for today’s logistics teams.

📌 Why Logistics Scheduling Matters

The supply chain almost never runs in a straight line. Orders change, traffic builds up, the weather acts up, equipment breaks down, and customer demands shift. All these moving parts can cause serious headaches for anyone trying to keep schedules on track. That’s where logistics scheduling software comes in. It smooths out the chaos by:

- 🔁 Automating repetitive tasks

- 🧾 Tracking important details

- 📊 Generating clear, helpful reports

In other words, it can do in seconds what used to take your team hours — and with way fewer mistakes.

🎯 Benefits of effective logistics scheduling

When done right, logistics scheduling creates value across your entire operation:

- 🚛 Improved resource utilization – Vehicles, equipment, and people are used fully but not overworked. Less idle time = lower costs.

- 😊 Enhanced customer satisfaction – On-time, reliable deliveries build trust and boost repeat business. Customers love predictability.

- 💸 Cost reduction – Smarter routes, fewer shipments, and less downtime cut fuel and operating expenses. Some companies save 5–10% overall.

- ⏱️ Minimized delays and disruptions – Good schedules help avoid traffic, weather problems, and last-minute changes.

- 👀 Greater visibility into operations – Managers can track goods, see who’s doing what, and catch bottlenecks before they grow.

- 📦 Efficient inventory management – Coordinated schedules reduce both stockouts and overstock.

- 👷♀️ Better workforce management – Matching shifts with workload lowers overtime and keeps staff productive and happy.

- 📋 Compliance with regulations – Helps follow transport and labor rules (like rest breaks and hours-of-service limits).

- 📈 Flexibility and scalability – A strong schedule can handle changing demand and support business growth without the mess.

- 🙌 Happier employees, easier work – Automation means fewer errors and less spreadsheet stress. Teams can focus on meaningful tasks.

📊 These aren’t just theoretical wins. Companies using modern scheduling tools report:

- 🔼 Productivity boosts of 15–25%

- 🔽 Labor cost savings of 5–10%

Those are the kinds of numbers that get the CFO’s attention 💼.

💰 The cost of poor scheduling

Conversely, without effective scheduling, logistics operations suffer. You’re more likely to face incomplete orders, inventory shortages, and missed deadlines. Last‑minute rescheduling means drivers stay late and equipment sits idle, driving up overtime and fuel costs. Fines for regulatory non‑compliance can be hefty. Most damaging of all, customers who experience missed deliveries may take their business elsewhere.

⚡ Real‑World Pain Points and Objections

Even though the benefits are clear, many decision‑makers hesitate to adopt new software. On social forums like Reddit and in industry roundtables, logistics managers voice common objections:

Common objections and what’s really true:

- ❓ “Our operation is too unpredictable.”

Order volumes can change daily, and managers worry that software can’t keep up. Actually, modern systems use demand forecasting and real-time updates to handle exactly this kind of chaos. - 🛠️ “We’re unique.”

Some think no ready-made tool fits their special workflows. In truth, many systems are highly configurable, with integration options and skill-based task assignments tailored to unique needs. - 💰 “It’s too expensive to implement.”

Upfront costs for software and training may seem high. However, most companies see labor cost cuts of 5–10% and productivity gains that quickly pay for the investment. - 📊 “We already use spreadsheets.”

Manual spreadsheets hide costs in hours of data entry, mistakes, version mix-ups, and risks with compliance. They can’t offer real-time insights or automate checks. - 🤖 “We’ll lose control.”

Some leaders fear automation will replace human judgment. Actually, scheduling software supports planners by automating routine tasks—freeing them up to focus on smart, strategic decisions. - 👥 “Our team won’t adopt it.”

Change can be tough. But careful rollout plans, involving key people early, and solid training help teams embrace new tools smoothly.

Recognizing these concerns early helps leaders tackle them head-on. The rest of this guide will give you the info and context to make smart decisions about logistics scheduling software.

🔨 Key Features to Look For in Logistics Scheduling Software

Choosing the right solution requires understanding which capabilities drive the biggest impact. Below are features that logistics managers consistently highlight as non‑negotiable.

⚙️ Automated and demand-based scheduling

Manual scheduling is time-consuming and full of mistakes. The best tools automatically assign shifts based on set rules and demand forecasts. Using past data and shipment predictions, they match labor to workload — cutting overtime, avoiding overstaffing, and making sure every shift is covered.

🛣️ Route-based planning and integration

Schedules and routes go hand in hand. Good employee shift scheduling software aligns staff availability with delivery routes and transportation plans. Integrated route optimization ensures drivers take the most efficient paths, reducing miles driven and fuel used — which means fewer last-minute changes and better on-time delivery.

🏢 Multi-location and shift marketplace support

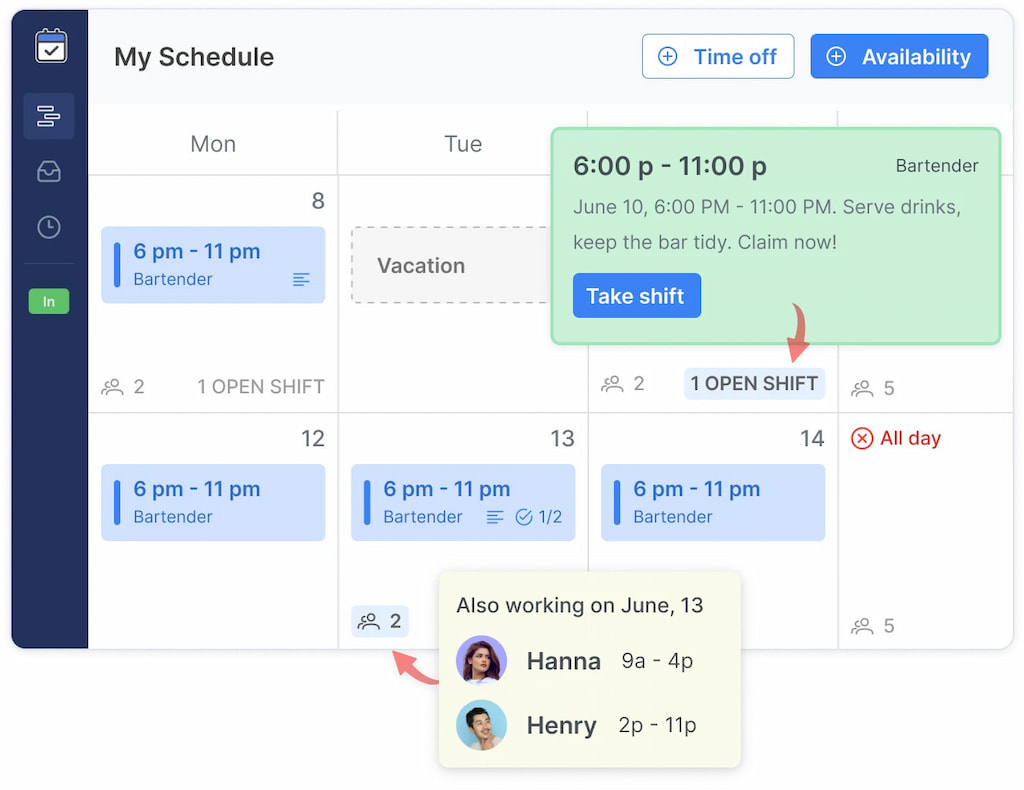

Many logistics companies work across several warehouses or hubs. A centralized scheduler coordinates staff across all sites. Advanced systems include shift marketplaces where employees can swap or pick up shifts, keeping coverage strong while giving workers flexibility.

🎓 Skills-based assignment and competency mapping

You can’t put an untrained worker on a forklift or a new driver on a tricky route. Skills-based assignment matches tasks to employees based on their qualifications and experience. A competency matrix ensures the right person fills each role — improving safety and efficiency.

📱 Mobile accessibility and self-service

Warehouse staff and drivers aren’t always at a desk. Mobile access lets them check schedules, clock in/out, request time off, and get notifications wherever they are. This cuts miscommunication and builds transparency. Plus, employees can set their availability to help balance work and life.

📋 Compliance and labor law management

Rules on hours of service, breaks, overtime, and predictive scheduling are complex. Software should enforce these automatically and generate compliance reports. Features that track driver hours and alert managers to potential violations help protect against fines and legal trouble.

📊 Real-time visibility and analytics

Effective schedulers provide dashboards showing staffing levels, productivity, and possible scheduling gaps. Real-time data helps managers react to surprises like demand spikes or delays. Analytics also reveal patterns over time to guide better decisions.

🔗 Integration with existing systems

Most logistics operations use warehouse management (WMS), transportation management (TMS), and HR/payroll software. Your scheduler should connect seamlessly with these systems to avoid duplicate work and keep payroll and inventory accurate. This also supports features like automatic order fulfillment and label printing.

📈 Scalability and customization

Your software needs to grow with your business and fit your unique workflows. Look for solutions that handle more users, locations, and complex rules without slowing down. Custom fields, shift templates, and configurable permissions help tailor the system to your needs.

🔒 Security and data privacy

Handling employee data requires strong security and compliance with laws like GDPR. Make sure your vendor offers strict access controls and follows industry standards to keep your data safe.

👀 Evaluating Logistics Staff Scheduling Software: A Comparison Table

When comparing options, map your requirements against available features. The table below summarizes key capabilities and how they differ between a spreadsheet‑based approach, a basic scheduling tool, and a modern solution like Shifts by Everhour.

| Feature | Spreadsheets | Generic Scheduling Tool | Shifts by Everhour |

| Automated shift assignment | Manual formulas prone to errors | Basic templates | Demand‑based algorithm with conflict checks |

| Route integration | None; separate routing systems | Limited | Full route‑based scheduling and integration with logistics management tools |

| Multi‑location management | Separate tabs per site | Limited | Centralized multi‑warehouse scheduling and shift marketplace |

| Skills and certifications tracking | Manual notes | Basic roles | Competency matrix and skills‑based assignment |

| Mobile self‑service | None | Simple viewing | Mobile app for clock‑in/out, availability, shift swaps |

| Compliance management | Manual law tracking | Partial | Automated hours of service, break compliance, and regulatory reporting |

| Real‑time analytics | Static data | Limited dashboards | Live dashboards and historical trends for labor costs and productivity |

| Integration with WMS/TMS/HR | Manual export/import | Varies | Seamless integrations and API support |

| Scalability | Quickly becomes unwieldy | Moderate | Designed to scale across teams and locations |

| Implementation complexity | Low but inefficient | Medium | Phased implementation with training and support |

✏️ Implementation Best Practices

Choosing the right tool is only half the battle. To realize the full benefits of logistics scheduling software, follow these best practices during implementation:

- 🔍 Conduct a needs assessment: Understand your current challenges, how order volumes change, staffing patterns, and regulatory needs before picking a solution.

- 🤝 Involve stakeholders: Include warehouse supervisors, drivers, dispatchers, and HR early in the selection and rollout. Their input helps make the system fit real workflows.

- 🔗 Plan data integration: Collaborate with IT to connect the scheduler with your existing WMS, TMS, and HR systems.

- 🚀 Roll out in phases: Start small—choose one facility or department to test and fix issues before expanding company-wide.

- 🎓 Invest in training: Provide thorough training to ensure high adoption and proper use. Keep support available as employees get used to the new system.

- 📊 Establish metrics: Define success measures like labor costs, schedule adherence, overtime, and employee satisfaction. Use dashboards to track progress and spot areas to improve.

Implementation is a process, not a one‑time event. Document what works, gather feedback, and iterate.

✍️ Challenges in Logistics Scheduling

While the benefits are clear, logistics scheduling comes with its own set of challenges that your workforce management software needs to handle:

🔄 Complexity of scheduling tasks

Coordinating delivery routes, vehicle capacity, driver availability, customer needs, and special equipment is tricky. The wrong mix causes bottlenecks, idle resources, or exhausted staff.

📉 Uncertainty in demand and supply

Sudden order spikes or supplier delays can throw plans off. Your scheduler must adjust in real time and forecast demand well to avoid shortages or overstaffing.

🌦️ External factors

Traffic jams, accidents, bad weather, and road closures all affect delivery times. Systems that use live traffic updates and weather alerts help reduce disruptions.

⚖️ Balancing efficiency with flexibility

Rigid schedules can’t adapt to surprises; overly flexible ones lose efficiency. The best tools strike the right balance between order and adaptability.

👷 Workforce-specific challenges

- Warehouse operations face shifting demand, multiple work zones, and special gear. Managers must staff receiving, picking, packing, and shipping while accounting for forklifts, pallet jacks, and night shifts.

- Driver shift optimization needs to follow hours-of-service rules, assign routes based on experience, handle real-time changes, manage fatigue, and balance workloads.

- Dock scheduling requires coordinating carrier appointments and workforce allocation. This includes appointment-based staffing, cross-dock coordination, equipment use, yard movements, and flexible teams.

- Regulatory compliance around service hours, breaks, and overtime must be tracked and documented. Laws about predictive scheduling and fair workweeks are tightening.

- Advanced technology integration like AI, machine learning, IoT, predictive analytics, digital twins, and autonomous systems offers big advantages. Your software should support these to stay future-ready.

Recognizing these challenges helps you choose software strong enough to tackle them all.

🔮 Future Trends in Logistics Scheduling

Looking ahead, three major trends are reshaping logistics scheduling:

- 🤖 Automation and AI – Artificial intelligence and automation play a bigger role in routing, workforce scheduling, and real-time updates. Machine-learning algorithms analyze past patterns to suggest the best schedules and adjust to changes.

- 🌱 Sustainability and eco-friendly practices – As environmental concerns grow, scheduling must reduce emissions by optimizing routes and balancing loads. Software that tracks carbon footprints and supports green practices will become standard.

- 📡 Integration of IoT and real-time data – Sensors on vehicles, forklifts, and inventory provide live location and status updates. This data powers scheduling algorithms to boost accuracy and resilience. Digital twins and predictive analytics further improve planning.

Forward-thinking operations leaders should evaluate solutions that embrace these trends. Investing early could give a strong competitive advantage as the market changes.

🙄 Why Spreadsheets and Generic Tools Fall Short

It’s tempting to think that a spreadsheet or general workforce tool can handle logistics schedules. However, logistics operations are far more complex than a typical retail schedule or office rota. Spreadsheets require manual data entry, lack real‑time visibility, and cannot enforce compliance rules. Version control becomes a nightmare when multiple supervisors update the same file. Generic scheduling tools may work for coffee shops but lack route integration, skills‑based assignment, and multi‑location support.

➡️ The result? Hidden costs such as overtime, fuel wastage, employee turnover, and regulatory fines. Modern logistics demands purpose‑built scheduling solutions.

💪 Shifts by Everhour: A Natural Solution for Logistics Scheduling

As an operations leader, you don’t want just another tool on your tech stack. You need a partner that understands the realities of logistics – the unpredictability, the compliance pressures, the human element. Shifts by Everhour is a staff scheduling platform designed to simplify even the most complex logistics operations.

❓ What Shifts can do for you?

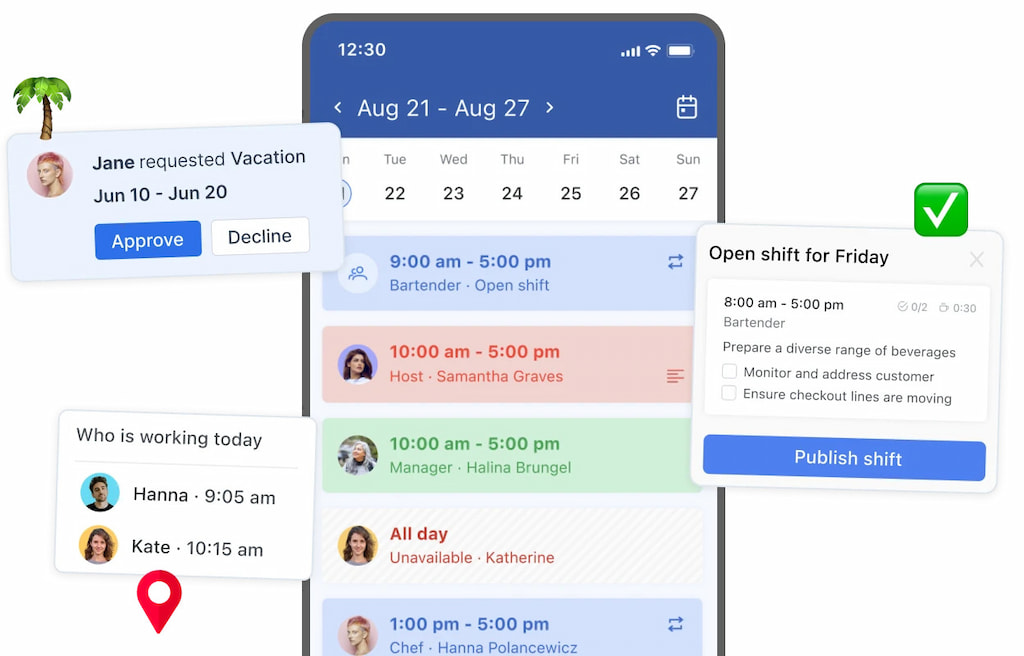

Shifts by Everhour automates the entire scheduling process and provides the following benefits:

- Increase employee productivity – Automated scheduling ensures the right people are in the right place at the right time. By removing manual allocation, Shifts helps your team focus on execution rather than paperwork.

- Reduce labor costs – Smart scheduling prevents overstaffing and eliminates unnecessary overtime. Companies using Shifts report up to a 20% reduction in labor costs.

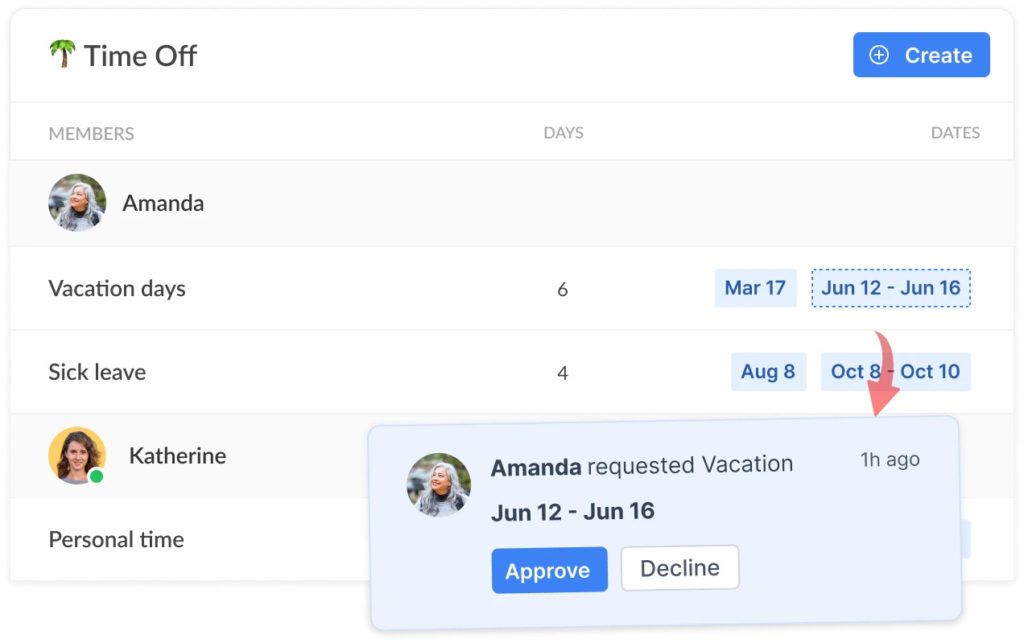

- Improve employee satisfaction – Employees can view their schedules, request time off, and communicate through the app. 95% of users report improved employee satisfaction.

- Enhance compliance – The platform helps you stay compliant with labor laws and regulations, reducing risk.

- Provide real‑time insights – Dashboards give you access to real‑time data and analytics for data‑driven decisions.

✅ According to Everhour, Shifts users experience a 30% increase in scheduling efficiency, save an average of 15 hours per month on scheduling tasks, and see labor costs drop by up to 20%.

✨ Key capabilities for logistics

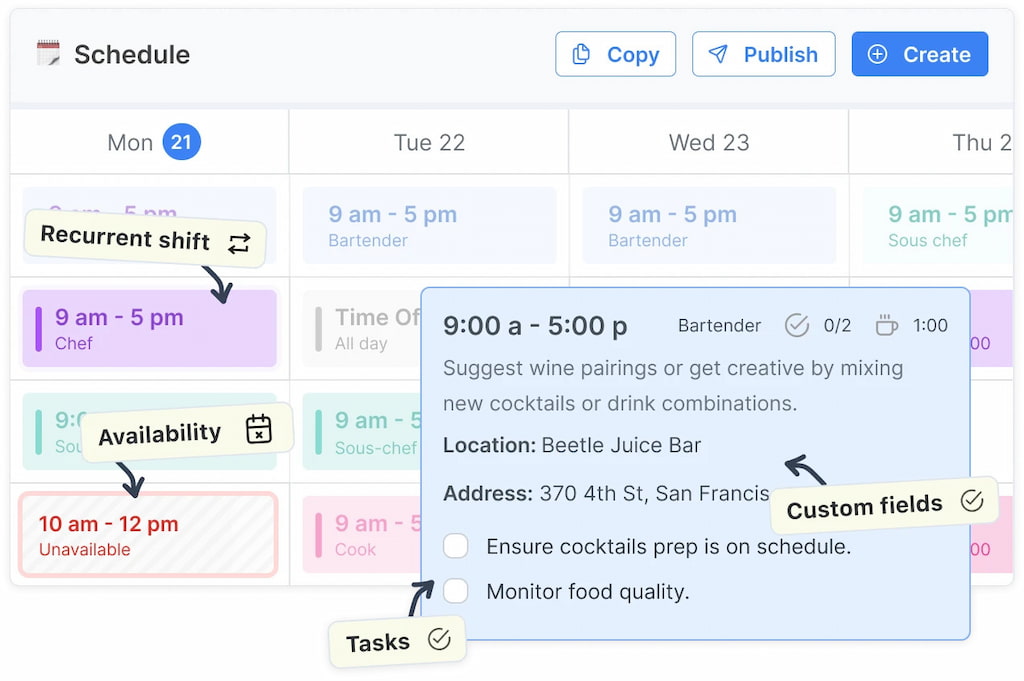

🗓️ Scheduling and shift creation

Easily build schedules from scratch or use templates. Group employees by job type, department, or location. Avoid conflicts with availability and time-off management.

📅 Availability management

Employees set their availability to prevent scheduling when they’re unavailable. Especially helpful for drivers and warehouse staff with varying personal commitments.

📱 Mobile clock-in and clock-out

Drivers and warehouse workers can view schedules and log hours on their phones — simplifying time tracking and cutting payroll errors.

🧾 Attendance and payroll

Centralized timesheets let you track hours and make adjustments with notes. Integration with payroll systems reduces admin tasks.

⏳ Time-off management

Manage vacation, sick leave, and other absences with clear categories. Generate reports to avoid understaffing.

📊 Analytics and insights

Get insights on labor costs and sales targets to fine-tune schedules based on real demand — linking scheduling directly to business results.

💬 Review and feedback

Customers say Shifts improves scheduling, communication, and productivity. Ask for case studies or demos to see how it fits your needs.

🚚 Why Shifts is great for logistics

- Complex shift support – Handles day, night, split, and rotating shifts, including long 12-hour driver shifts with rest and overtime rules.

- Multi-location & role grouping – Manage separate teams for warehouses, cross-docks, and drivers with different start times and roles.

- Scalable – From 10 to 1,000+ employees, supports adding locations and departments without hassle.

- Easy to use – Drag-and-drop interface that’s intuitive for spreadsheet users. Phased rollout and free training available.

Shifts doesn’t replace human judgment — it frees managers from admin work so they can focus on safety, strategy, and customer experience.

🧠 Case Study: From Chaos to Control

Imagine a mid-sized logistics company with two warehouses and a fleet of 50 trucks. Before using scheduling software, managers spent most Monday mornings building schedules in Excel. When orders changed, they scrambled to call drivers and reassign shifts. Employee morale dropped because schedules were posted late and often changed. Plus, overtime costs cut into profits.

After adopting a demand-based scheduling platform, the company saw quick results. The software forecasted staffing needs based on past order volumes and let employees set availability via a mobile app. Dispatchers adjusted routes in real time, and drivers received updated schedules on their phones.

- 🔻 Overtime costs dropped by 12%

- 📦 On-time deliveries improved by 8%

- 🚚 Warehouse throughput increased by 20%

- 🙂 Employee satisfaction rose thanks to fair, predictable schedules

❓ How to Choose Logistics Scheduling Software: A Step‑by‑Step Approach

Decision-makers often feel overwhelmed by all the options. Use this clear process to guide your selection:

- 🎯 Define your goals and KPIs: Identify pain points like overtime, labor costs, or customer complaints. Set clear success targets such as reducing overtime by 10% or improving on-time deliveries by 5%. Link these goals to scheduling metrics.

- 📋 Inventory your existing systems: List all warehouse, transportation, and HR systems that need to work with your scheduler. Note any unique workflows or constraints.

- 🗣️ Gather requirements from stakeholders: Interview supervisors, drivers, HR, and finance teams. Find out must-have features like mobile access, shift swapping, or skills tracking.

- 🔍 Research vendors: Evaluate based on features, scalability, integration, security, and support. Narrow down to 3–5 candidates.

- 💻 Request demos and trials: Test software with your own data if possible. Assess ease of use, setup, and reporting.

- 💰 Calculate total cost of ownership: Include subscription, implementation, training costs, and savings from efficiency gains. Ask vendors for ROI examples.

- 🚀 Plan phased implementation: Start with one facility or department. Gather feedback and adjust before a full rollout.

- 🎓 Train and support: Provide thorough training for managers and staff. Set up a support channel for questions during rollout.

- 📈 Monitor and optimize: Use your KPIs to track success, find gaps, and improve scheduling continuously.

🔃 Don’t forget change management

New technology means change. Communicate early and often, address worries about job security and workload, and highlight how automation cuts admin tasks and creates fairer, more predictable shifts. Celebrate quick wins to keep momentum going.

🔁 Beyond Scheduling: Integration with the Rest of the Supply Chain

Logistics scheduling does not exist in a vacuum. It intersects with procurement, manufacturing, inventory management, transportation, customer service, and finance. Modern logistics scheduling software should integrate with:

- 📦 Inventory and warehouse management systems (WMS): Real-time stock levels and automated reordering help prevent stockouts.

- 📝 Order processing and fulfillment: Smoothly convert orders into fulfillment tasks with accurate documentation and shipping labels.

- 🛣️ Route optimization tools: Smarter routes reduce mileage, fuel costs, and emissions.

- 📊 Real-time data and reporting platforms: Dashboards consolidate key metrics like freight costs, shipment times, and labor utilization.

- 💼 Payroll and HR systems: Accurate time tracking and pay calculations cut errors and reduce admin time.

By connecting these systems, you create a unified data ecosystem that enables proactive decision‑making and continuous optimization.

🍀 Logistics Scheduling in a Greener, More Automated Future

Sustainability and automation are no longer optional in supply chains. As environmental regulations tighten and corporate ESG commitments grow, logistics leaders must focus on reducing the carbon footprint of their routes.

Scheduling software now includes features like:

🌿 Route optimization and load balancing to support greener operations

📊 Carbon dashboards to track environmental impact

🔌 Integration with electric vehicle fleets for cleaner transportation

Meanwhile, automation and machine learning are improving scheduling accuracy every day. Key innovations include:

- 🤖 Algorithms that adapt to traffic patterns, weather forecasts, and market demand

- 📡 IoT devices sending real-time data from vehicles, equipment, and inventory

- 🧠 Digital twins allowing planners to simulate scenarios before making changes

- 🚛 Autonomous vehicles and robots scheduled alongside human workers, coordinated by advanced systems

The future of logistics scheduling blends sustainability with cutting-edge automation to create smarter, cleaner, and more efficient supply chains.

🔎 Final Thoughts: Logistics Staff Time Tracking and Scheduling Software

Logistics scheduling can be your secret weapon—or your daily headache. The right tool doesn’t just save time—it drives efficiency, reduces costs, and keeps teams aligned.

Tools like Shifts by Everhour bring automation, compliance, and real-time visibility to the forefront. If you’re still relying on spreadsheets or outdated platforms, now’s the time to rethink. A quick trial could show just how much smoother your ops could run.

Discover the best plumbing staff scheduling software to streamline your team and boost efficiency today!

Streamline your lawn care scheduling 🌱 — save time, reduce no-shows, and keep every yard looking its best!